Popular in your industry

Top categories

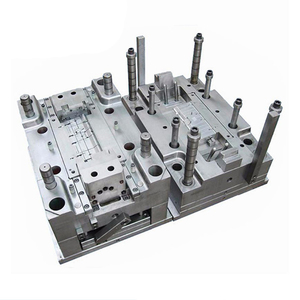

About toothbrush injection mold

Understanding Toothbrush Injection Molds

The toothbrush injection mold is a specialized tool used in the mass production of toothbrushes. This precision equipment is designed to shape the bristles and handle of a toothbrush, ensuring consistency and functionality in every product. Injection molding for toothbrushes is a complex process that requires a meticulously crafted mold to produce the desired results.

Types and Applications

There are various types of molds available, each serving a specific purpose in the toothbrush manufacturing process. From single-cavity molds for bespoke designs to multi-cavity molds for large-scale production, the choice of a mold depends on the scale and specifics of the manufacturing project. These molds are used in conjunction with injection molding machines to produce toothbrushes in various shapes and sizes, catering to a diverse market demand.

Features and Materials

A toothbrush injection mold is characterized by its robust construction and precision engineering. Common materials used include stainless steel and aluminum, chosen for their durability and resistance to the high pressures of injection molding. The design of the mold is critical, incorporating features such as runner systems, gates, and cooling channels that directly impact the efficiency and quality of the production process.

Advantages of Standardization

Standardizing certain elements of the mold, such as lift bars, connection sizes, and clamp slots, can significantly reduce production costs and increase compatibility across different molding machines. This approach not only streamlines the manufacturing process but also simplifies mold interchangeability and maintenance.

Design for Manufacturing (DFM)

The initial phase of creating a toothbrush injection mold involves a Design for Manufacturing (DFM) analysis. This is a critical step where the mold-making shop evaluates the product design to determine the most efficient way to construct the mold. The DFM ensures that the mold is designed with manufacturability in mind, balancing cost, production time, and product quality.

Choosing the Right Mold on Alibaba.com

Selecting the appropriate toothbrush injection mold is a decision that impacts the quality and cost-effectiveness of toothbrush production. Alibaba.com hosts a vast network of mold shops, offering a platform for businesses to source molds that align with their production requirements. By leveraging the information available on the platform, buyers can make informed decisions on the molds that best fit their quality specifications and production goals.