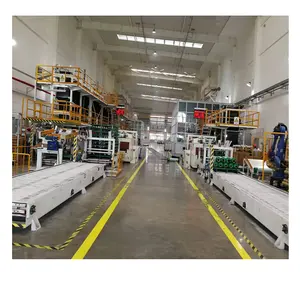

Rubber Insulation Production Line Overview

The rubber insulation production line is a sophisticated assembly of machinery designed for the manufacturing of rubber insulation materials. This production line is pivotal in creating various insulation products, which are essential components in electrical safety and thermal applications. The line typically encompasses equipment for extrusion, cooling, and cutting, ensuring a seamless transformation of raw materials into finished goods.

Types of Rubber Insulation Machinery

Within the realm of rubber insulation production, machinery can be categorized mainly into single screw and double screw extruders. Single screw extruders are suitable for straightforward, less complex rubber insulation tasks. In contrast, double screw rubber insulation production lines are recognized for their efficiency and higher output, making them ideal for more demanding production requirements. The choice between these types hinges on the specific needs of the production task at hand.

Applications in Industry

Rubber insulation is critical in various sectors, particularly in electrical safety. Products such as electrical hand gloves 33kv and 33kv rubber mat are essential for protecting workers from high-voltage environments. These items are just a few examples of the end products that can be fabricated using a rubber insulation production line, showcasing the line's versatility in producing a range of safety-related materials.

Features and Advantages

A rubber insulation production line is engineered to handle a spectrum of rubber types, offering flexibility in production. The lines are designed for optimal thermal control, ensuring that the rubber is processed under conditions that maintain its insulative properties. The advantage of using such specialized lines includes the ability to produce consistent, uniform insulation materials, which is crucial for the reliability of the end products.

Material Considerations

The materials used in a rubber insulation production line are selected based on their thermal and electrical insulating properties. The production line must be compatible with these materials to ensure that the final products meet the required safety standards. Materials are chosen for their durability and performance, ensuring that the insulation products can withstand the conditions they will be exposed to in their application.

Choosing the Right Production Line

Selecting the appropriate rubber insulation production line involves considering the material compatibility, production capacity, and the specific type of insulation products being manufactured. It is crucial to assess the line's features, such as the extruder type, to ensure it aligns with the production goals. The efficiency of the line directly impacts the throughput and quality of products like electrical hand gloves 33kv and 33kv rubber mat, which are indispensable for electrical safety.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4