Popular in your industry

Related Searches:

Top categories

About platform extrusion profile

Exploring the Versatility of Platform Extrusion Profiles

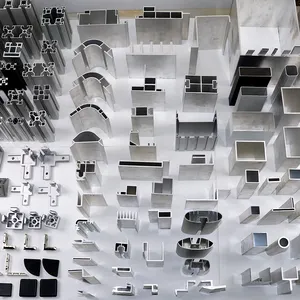

Platform extrusion profiles are integral components in a myriad of industries, serving as foundational elements in construction, manufacturing, and design. These profiles are crafted through a process that pushes material, typically aluminum, through a die to create complex cross-sectional shapes. This method affords immense flexibility in design and application, making platform extrusion profiles a go-to solution for professionals across various sectors.

Types and Shapes of Platform Extrusion Profiles

The diversity of platform extrusion profiles is evident in their range of shapes and sizes. From L-angled brackets to T-shaped bars, each profile is engineered to meet specific structural requirements. Hollow tubes and solid round tubes cater to both lightweight applications and those demanding robust strength, while specialized forms like J caps and Z clips are tailored for precise functions in complex assemblies.

Material Specifications and Surface Treatments

Most platform extrusion profiles are composed of 6000 series aluminum alloy, known for its balance of strength and ductility. The temper of these profiles can vary, typically ranging from T3 to T8, indicating the level of hardness and strength due to heat treatment. Surface treatments are diverse, including options like anodizing, which enhances corrosion resistance and allows for color customization, and powder coating, which provides a durable and attractive finish.

Applications Across Industries

The application of platform extrusion profiles spans across various industries. In construction, they provide structural support and aesthetic value. The adaptability of these profiles makes them ideal for office furniture frameworks, interior design elements, and even intricate lighting fixtures. The automotive sector utilizes these profiles for parts that require a balance of weight and strength, while in plumbing, their precision shapes facilitate efficient systems.

Advantages of Using Platform Extrusion Profiles

Choosing platform extrusion profiles brings several advantages. Their versatility in shape and material allows for customization to specific project needs. The durability of aluminum, combined with appropriate surface treatments, ensures longevity and resistance to environmental factors. Moreover, the aesthetic flexibility from various finishing processes, including wood grain effects for a natural look, enables these profiles to blend seamlessly into design schemes.

Customization and Aesthetic Options

Customization is a key feature of platform extrusion profiles, with suppliers offering tailored dimensions and thicknesses to suit unique project requirements. Aesthetic options are equally varied, with a spectrum of colors achievable through different surface treatments. Whether the need is for a polished, mirror-like finish or a matte texture, these profiles can be adapted to match the envisioned design palette.

Incorporating platform extrusion profiles into your project not only ensures structural integrity but also offers a breadth of design possibilities. Their adaptability, coupled with a range of finishing options, makes them a valuable asset in any construction or manufacturing plan.