Popular in your industry

Related Searches:

Top categories

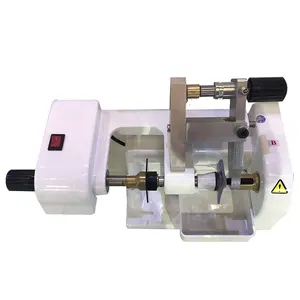

About plastic lens machinery

Introduction to Plastic Lens Machinery

Plastic lens machinery represents a specialized category of industrial equipment designed for the production of high-precision lens components. These machines are integral to sectors requiring meticulous lens crafting, such as consumer electronics, automotive industries, and medical device manufacturing. The machinery's core function is to shape plastic granules into precise lens dimensions through a process known as plastic injection molding.

Types and Applications

The versatility of plastic injection molding machines is evident in their ability to produce components for a diverse range of applications. From creating intricate parts for eyewear and cameras to larger lenses used in automotive lighting, the scope of these machines is vast. They are also employed in fabricating lenses for projectors and other optical devices, showcasing their adaptability across various industries.

Features and Materials

Modern plastic lens machinery is equipped with advanced features such as servo-valve single-cylinder systems, which enhance response rates and precision. The machinery is designed to handle various plastic materials, including PVC, ensuring that the end product meets the specific requirements of different applications. The incorporation of specialized screws in the machinery facilitates increased plasticizing capacity, crucial for achieving the desired lens weight and speed in production.

Advantages of Plastic Lens Machinery

Investing in plastic lens production equipment offers several advantages. The machinery's design minimizes wear resistance, reducing maintenance needs and operational costs. Additionally, the precise clamping force tailored to specific production requirements ensures efficient material use and energy consumption. This efficiency translates to a more sustainable production process and potentially lower overheads for businesses.

Construction and Durability

The construction of plastic lens molding machines focuses on durability and long service life. With a clamping force that can withstand significant external machining forces, these machines are built to resist the rigors of continuous industrial use. The steel bush in the clamping unit is structured to diminish lubrication effects, further enhancing the machine's longevity and reducing the frequency of lubricant oil replacements.

Choosing the Right Machinery

Selecting the appropriate plastic lens manufacturing machinery is crucial for businesses aiming to produce lenses with improved accuracy. Alibaba's platform connects buyers with a variety of machinery options, each designed to transform plastic granules into precise lens shapes. Prospective buyers can explore a range of machines with different capacities to find the one that aligns with their production needs and objectives.