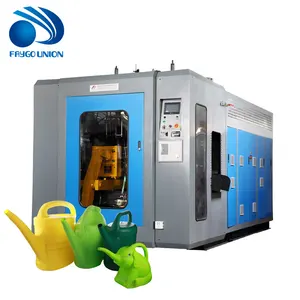

Introduction to Plastic Kettle Machines

Plastic kettle machines represent a significant category in the manufacturing sector, specifically designed for the production of plastic kettles and related products. These machines are integral to the process of injection molding, where plastic granules are transformed into a variety of sturdy and functional items. This introduction delves into the intricacies of these machines, their types, applications, and the features that make them essential for plastic production.

Types and Applications

The plastic injection molding equipment used in the creation of plastic kettles is versatile, catering to a range of industries from consumer electronics to food and beverage, as well as automotive components. These machines are adept at producing thin wall containers, caps, pails, and various PVC pipe fittings, showcasing their broad application spectrum.

Features and Materials

A plastic kettle machine is engineered for endurance and efficiency. The special screws incorporated into these machines enhance the plasticizing capacity, ensuring a consistent shot weight and speed during the molding process. The clamping unit, a critical component, is designed to provide the precise force needed for each specific task, with a force range that can resist significant external machining forces. The steel bush within this unit is structured to minimize wear resistance, thereby reducing the need for frequent lubrication and associated costs.

Advantages of Modern Molding Machines

Investing in a plastic injection molder comes with the advantage of improved accuracy and durability. The single-cylinder system equipped with a servo-valve ensures a responsive molding process, which is crucial for maintaining low defective rates and meeting industry standards. Additionally, the continuous design enhancements contribute to the longevity and service life of these machines, making them a valuable asset for businesses in the plastic processing industry.

Specialized Design and Precision

The design of a plastic molding machine is specialized to handle different sizes of preforms, allowing for a wide range of product dimensions. This specialization is complemented by the exact clamping force provided by the machine, tailored to the specific requirements of the task at hand. The new structure of the steel bush in the clamping unit not only enhances the machine's durability but also contributes to the precision of the final product.

Choosing the Right Machine for Your Business

Selecting the appropriate plastic kettle manufacturing machine is crucial for any business looking to produce plastic kettles and related products. The machines available on Alibaba.com are designed to meet various production needs, ensuring that businesses can find the right fit for their specific requirements. By browsing the extensive listings, buyers can connect with wholesalers offering machines that shape plastic granules into precise dimensions, enhancing the efficiency and output of their manufacturing processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4