Popular in your industry

Related Searches:

Top categories

About plastic bag manufacturing equipment

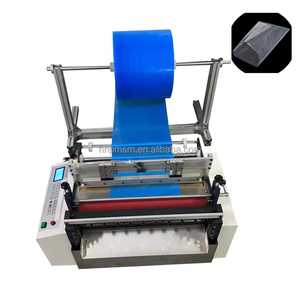

Introduction to Plastic Bag Manufacturing Equipment

Plastic bag manufacturing equipment is essential machinery used in the production of various types of plastic bags, including poly bags, PP woven bags, and polythene packs. This equipment plays a crucial role in the packaging industry, providing efficient and high-quality solutions for businesses looking to manufacture plastic bags in bulk.

Technical Specifications and Capabilities

Plastic bag manufacturing equipment comes with a range of technical specifications to meet different production needs. These machines are equipped with advanced features such as high-speed operation, precise cutting mechanisms, and adjustable sealing options. The power capability of these machines typically ranges from 35-40 hp, allowing for continuous and reliable production processes.

Types of Plastic Bag Machines

There are various types of plastic bag machines available from reputable plastic bag machine manufacturers. These include flat bag making machines, bottom sealing machines, and side seal bag machines. Each type serves a specific purpose in the plastic bag manufacturing process, offering unique features and capabilities to cater to different production requirements.

Key Features and Advantages

The plastic bag manufacturing equipment is designed with key features that enhance efficiency and productivity. Some common features include automatic tension control, photoelectric tracking, and temperature control systems. These features ensure precise bag production and consistent quality output. The advantages of using such machinery include increased production speed, reduced labor costs, and improved product quality.

Choosing the Right Plastic Bag Machinery

When selecting plastic bag manufacturing equipment, it is essential to consider factors such as production capacity, bag size versatility, and ease of operation. Additionally, looking for poly bag sealing machine suppliers who offer reliable after-sales support and maintenance services is crucial for uninterrupted production. Choosing a reputable manufacturer with a proven track record in the industry is key to investing in high-quality equipment.

Usage Scenarios and Applications

Plastic bag manufacturing equipment finds applications across various industries, including food packaging, retail, and e-commerce. These machines are versatile and can produce a wide range of plastic bag types to meet different packaging needs. Whether it's for packaging fresh produce or retail merchandise, plastic bag machinery plays a vital role in ensuring efficient and sustainable packaging solutions.

Maintenance and Care Tips

To ensure the longevity and optimal performance of plastic bag manufacturing equipment, regular maintenance is essential. This includes cleaning the machine components, lubricating moving parts, and conducting routine inspections for wear and tear. Following the manufacturer's guidelines for maintenance and scheduling preventive maintenance checks can help prevent unexpected downtime and extend the lifespan of the equipment.

Enhancing Production Efficiency with PP Woven Bag Machinery

In addition to plastic bag manufacturing equipment, businesses can also benefit from investing in PP woven bag machinery for producing durable and eco-friendly woven bags. PP woven bags are widely used for packaging agricultural products, chemicals, and construction materials. These machines offer efficient production processes for weaving and printing on PP woven fabric, enhancing the overall packaging capabilities of businesses.

Exploring Poly Bag Machine Manufacturers for Custom Solutions

Businesses looking for customized plastic bag manufacturing solutions can collaborate with experienced poly bag machine manufacturers to develop tailored machinery. These manufacturers specialize in designing and building poly bag machines to meet specific production requirements, including bag size variations, printing options, and automation features. By partnering with poly bag machine manufacturers, businesses can achieve personalized solutions that align with their unique packaging needs.

Investing in Sustainable Packaging Solutions with Polythene Pack Karne Ki Machine

The polythene pack karne ki machine offers businesses an environmentally friendly packaging solution for producing polythene packs. These machines are designed to minimize waste and optimize material usage, making them ideal for businesses focused on sustainable packaging practices. By investing in polythene pack machinery, businesses can reduce their carbon footprint and contribute to a more sustainable future.