Popular in your industry

Related Searches:

Top categories

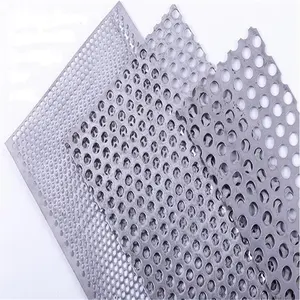

About perforated steel roll

A perforated steel roll is a versatile material widely used in various industrial and commercial applications. This product is characterized by a series of holes that are uniformly punched or drilled over a large sheet of steel that is then rolled for ease of transport and handling. The holes can be of various shapes and sizes, and the roll itself can be made from different types of steel, including mild steel, stainless steel, and galvanized steel, to suit specific requirements.

Types and Materials of Perforated Steel Rolls

Delving deeper into the types of perforated steel rolls, we find that each variant serves a unique purpose. Mild steel rolls are favored for their malleability and are commonly used in applications where they can be easily shaped and welded. Stainless steel rolls, known for their resistance to oxidation and corrosion, are ideal for use in food processing, medical, and marine environments. Galvanized steel rolls are chosen for their durability and resistance to harsh weather, making them suitable for outdoor structures and fencing. The choice of material significantly impacts the roll's performance in specific environments, with each offering a balance of strength, flexibility, and resistance to various elements.

Structure and Weave Styles of Perforated Steel

The physical structure of a perforated steel roll is a testament to precision engineering. The base metal is meticulously processed to create a uniform pattern of holes. This is achieved through various methods such as punching, drilling, or laser cutting. The structural integrity of the roll is maintained by the unperforated metal that surrounds each hole, which is calculated to ensure the roll retains its strength and form. The operation of these components together provides a material that is both lightweight and durable. The weave style, whether it be plain, Dutch, or twill, further influences the roll's properties, such as its tensile strength and its ability to filter and allow the passage of air and light.

Materials and Properties of Perforated Steel Rolls

The materials used in perforated steel rolls are selected based on their mechanical properties and suitability for the intended application. Stainless steel is chosen for its ability to withstand high temperatures and resist corrosion, making it ideal for use in environments where hygiene and cleanliness are paramount. Galvanized steel, coated with a layer of zinc, offers protection against rust and is often used in outdoor settings. The properties of these materials, such as tensile strength, ductility, and resistance to environmental factors, are critical in determining the roll's longevity and functionality in various applications.

Business Usages and Applications of Perforated Steel

In the business realm, perforated steel rolls are indispensable in sectors such as architecture, where they contribute to aesthetic designs while providing functional benefits like sun shading and privacy screening. In the manufacturing industry, they are used in the production of filters, guards, and grilles, playing a crucial role in protecting machinery and personnel. The agricultural sector utilizes these rolls in equipment screens to protect crops and machinery from debris. Each application leverages the unique properties of perforated steel to create value, enhance safety, and improve operational efficiency.

Functions and Tasks of Perforated Steel Rolls

The primary function of a perforated steel roll is to provide a material that combines the strength of steel with the benefits of a reduced weight and increased functionality. These rolls are designed to perform tasks such as filtering, screening, protecting, and ventilating. In industrial settings, they are used as part of machinery for sorting and grading. The design of the perforations allows for specific tasks such as controlling the passage of air, light, and materials, which is essential in processes like drying, cooling, and sound reduction.

Features and Unique Selling Points

The distinct characteristics of perforated steel rolls include their high corrosion resistance, which is especially pronounced in stainless steel and galvanized options. The uniformity of the hole patterns not only contributes to the aesthetic appeal but also ensures consistent performance across the entire surface area. These unique selling points set them apart from competitors, as they offer a combination of durability, versatility, and precision that is hard to match.

Benefits and Positive Outcomes

The benefits of using perforated steel rolls are manifold. They solve problems such as the need for effective ventilation in buildings, the requirement for protective barriers that do not obstruct light, and the demand for materials that can perform under extreme conditions without degradation. The positive outcomes include improved safety, enhanced functionality, and a balance between privacy and transparency in architectural applications.

How to Use and Operate Perforated Steel Rolls Effectively

Effective operation of perforated steel rolls involves understanding the specific application requirements. For instance, in filtration systems, the size and shape of the perforations must match the type of material being filtered. When used in architectural designs, the rolls should be installed with consideration for aesthetic alignment and structural support.

How to Choose the Right Perforated Steel Roll

Selecting the right perforated steel roll requires an assessment of the environment in which it will be used, the type of stress it will be subjected to, and the specific function it needs to perform. Factors such as the material's resistance to corrosion, its strength, and the size and pattern of the holes should be matched to the application's demands.

How to Clean and Maintain Perforated Steel Rolls

Cleaning and maintaining perforated steel rolls is essential for ensuring their longevity. Regular cleaning with non-corrosive cleaners, inspection for signs of wear, and immediate repair of any damage are key to maintaining their appearance and functionality. Proper maintenance routines can significantly extend the life of these materials.

How to Install Perforated Steel Rolls

Installation of perforated steel rolls should be carried out with precision. Ensuring that the rolls are securely fastened and aligned correctly is crucial for their performance. It is often advisable to consult with professionals who have experience in handling and installing these materials to avoid any potential issues.

What are the customization options for perforated steel rolls?

Customization options for perforated steel rolls are extensive. Processing services such as cutting, bending, and decoiling allow for the material to be shaped and sized according to specific project requirements. Additionally, the choice of hole shapes, from round to square, and the color options, including silver, green, white, and black, enable a high degree of personalization.

What industries benefit most from using perforated steel rolls?

Industries that benefit most from using perforated steel rolls include construction, where they are used for sound barriers and ventilation systems; agriculture, for fencing and equipment screens; and manufacturing, where they serve as filters or guards. Their versatility also makes them popular in interior design and architectural applications.

How does the quality of perforated steel rolls impact its applications?

The quality of perforated steel rolls directly impacts their performance in various applications. High-quality steel with precise perforations ensures structural integrity, functionality, and aesthetic appeal. In applications such as filtration or protective barriers, the consistency and durability of the material are paramount for the safety and efficiency of the systems in which they are used.