Popular in your industry

Related Searches:

Top categories

About perforated plastic mesh panel

Exploring the Versatility of Perforated Plastic Mesh Panels

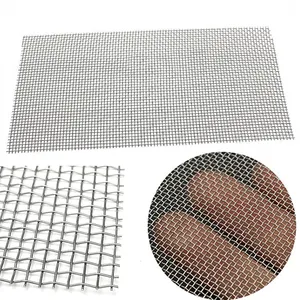

Perforated plastic mesh panels are a versatile material used in various industrial, commercial, and residential applications. These panels are crafted by creating multiple perforations in a plastic sheet, resulting in a mesh that combines durability with functionality. The unique design of these panels allows for excellent airflow and light penetration, making them an ideal choice for numerous projects.

Types and Applications of Perforated Plastic Mesh

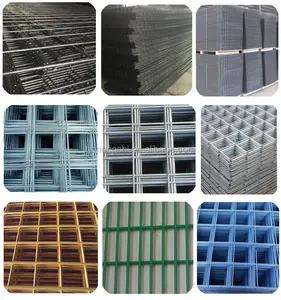

There is a diverse array of perforated plastic mesh types, each suited to specific applications. For instance, the lightweight nature of plastic mesh screening makes it perfect for creating protective barriers in agricultural settings, safeguarding livestock and crops. In construction, plastic mesh sheets are used to reinforce concrete, while in the home and garden, they serve as sturdy yet aesthetic garden fencing options. Industrial uses include filtration systems, where fine plastic mesh plays a crucial role in sieving and filtering processes.

Features and Materials

The manufacturing of perforated plastic mesh panels involves various materials, each selected for its properties. Polyethylene and polypropylene are common due to their resistance to chemicals and impact. The panels come in different shapes and sizes, with hexagonal, diamond, and square patterns being prevalent. The customization potential of these panels is significant, allowing them to meet the precise needs of any project.

Advantages of Perforated Plastic Mesh Panels

The advantages of using perforated plastic mesh are manifold. Their resistance to rust and corrosion makes them a long-lasting solution in harsh environments. The panels are also known for their ease of handling and installation, thanks to their lightweight nature. Moreover, the inherent strength of the material ensures that it can withstand significant stress, making it a reliable choice for various applications.

Environmental Impact and Sustainability

Environmental sustainability is a growing concern, and perforated plastic mesh panels are often recognized for their eco-friendly potential. Many of these panels are recyclable, reducing the environmental footprint. Additionally, the production process of plastic mesh is designed to minimize waste, further contributing to environmental conservation efforts.

Choosing the Right Perforated Plastic Mesh Panel

Selecting the appropriate perforated plastic mesh panel requires consideration of the specific application, environmental conditions, and desired longevity. While Alibaba.com facilitates the connection between buyers and a diverse range of suppliers, it is crucial to assess the specifications and material properties to ensure the mesh meets the project's requirements. With a comprehensive selection available, finding the right panel to tackle any challenge is streamlined and efficient.