Oval Paper Cutter: An Overview

The oval paper cutter is an essential tool in the paper production industry, designed to streamline the process of creating various paper products. This machinery is adept at handling tasks from embossing to folding, making it a versatile asset for businesses focusing on paper goods such as toilet papers, napkins, and other sanitary products.

Types and Applications

There are diverse types of oval shape paper cutters, each serving a specific function within the paper manufacturing sector. These machines cater to the needs of large-scale operations such as hotels, manufacturing plants, and paper processing industries. The applications range from crafting paper cups and serviettes to producing high-quality tissue papers.

Technical Features and Materials

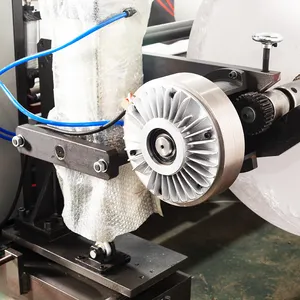

An oval paper cutter is engineered with precision, utilizing materials that ensure durability and efficiency. The embossing units can be configured with steel-to-steel or steel-to-rubber patterns, catering to custom design requirements. The slitting and folding units are integral for precise cuts and folds, crucial for the final product's quality.

Machine Specifications and Advantages

The specifications of an oval shape paper cutter vary, with smaller units weighing approximately 1,000kgs and larger ones reaching weights of 3,000kgs or more. These machines are designed to optimize production, with capacities ranging from 70 pcs/min to 3 tons per day. The integration of photoelectric technology enhances the machine's performance by monitoring operations and signaling alerts for paper shortages or malfunctions.

Automation and Control Systems

Modern oval paper cutters boast full automation, featuring PLC control panels for seamless operation. The automatic oil lubrication system ensures the longevity of the machinery, while the pneumatic systems driven by air compressors underscore the technological advancement of these cutters.

Choosing the Right Oval Paper Cutter

Selecting the appropriate oval shape paper cutter depends on the production scale and specific industry requirements. With various configurations available, it is crucial to consider factors such as machine weight, power usage, and production capacity to ensure the chosen equipment meets the operational demands.

![[JT-GM1400] CE Industrial High Speed Rotary Jumbo Roll To Sheet Automatic Paper Cross Sheeting Cutting Machine Cutter](https://s.alicdn.com/@sc04/kf/H87593ece2bdf47f4af53749107b8675aM.jpg_300x300.jpg)

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4