Popular in your industry

Related Searches:

Top categories

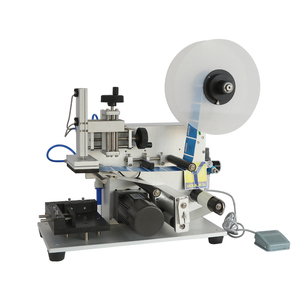

About manual bottle label machine

As the name suggests, a manual bottle label machine is a device designed to apply labels onto bottles. It is often used in small-scale manufacturing or by individuals who need to label bottles for personal or business use. These machines are typically user-friendly and do not require advanced technical skills to operate, making them a popular choice for those looking to streamline their labeling process.

Types of manual bottle label machines

There are several types of manual bottle label machines in the market. One common type is the manual label applicator, which is a simple and cost-effective device for applying labels to bottles. It usually consists of a base, a handle, and a label dispenser. The user places the bottle on the base, positions the label on the bottle, and then uses the handle to apply the label.

Another type is the manual bottle labeler, which is a more specialized machine designed specifically for labeling bottles. It often features adjustable settings to accommodate different bottle sizes and label types. In addition, there is a manual sticker labeling machine, which is a compact and portable device that allows users to apply self-adhesive stickers to bottles. It is often used in small-scale production or for labeling bottles in a home or hobby setting. Lastly, the Zonesun labeling machine is a popular brand in the labeling industry, known for its quality and efficiency in applying labels to various products, including bottles.

Pros and cons of manual bottle label machines

Manual bottle label machines offer several advantages. Firstly, they are cost-effective, making them an accessible option for small businesses or individuals. Secondly, they are versatile and can be used to label a variety of bottle sizes and shapes. Thirdly, they are easy to operate and do not require extensive training. Lastly, they are portable and can be used in different locations.

On the flip side, manual bottle label machines have some drawbacks. The manual operation can be time-consuming for large volumes of bottles. Additionally, the labeling process may not be as precise or consistent as with automated machines. Lastly, manual bottle label machines may not be suitable for high-production environments.

Tips for choosing manual bottle label machines

When choosing a manual labeling machine, several factors should be considered. Firstly, the type of labels to be used and the size and shape of the bottles are crucial. Secondly, the volume of bottles to be labeled should be taken into account. Thirdly, the ease of use and adjustability of the machine is essential. Lastly, the durability and maintenance requirements are vital for long-term use.