Popular in your industry

Related Searches:

Ready to Ship

Ready to Ship

Top categories

About induction cooking pcb board

An induction cooking PCB board is the electronic heart of an induction cooker, a modern kitchen appliance that has revolutionized cooking by using electromagnetic fields to heat pots and pans directly. Unlike traditional cooking methods, induction cooking is faster, more energy-efficient, and offers precise temperature control. The induction PCB board is responsible for managing the power and controls necessary to create the electromagnetic field that cooks the food.

Types of Induction Cooking PCB Boards

Induction cooking PCB boards come in various types, each designed to cater to different cooking needs and appliance sizes. From single-element boards for compact portable units to multi-element boards for full-sized ranges, the variety is extensive. Some boards are built for residential use with moderate power settings, while others are crafted for commercial settings where high power and durability are essential. The characteristics of these boards vary, with some offering additional functionalities like Bluetooth connectivity for smart cooking experiences.

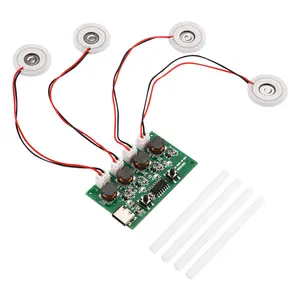

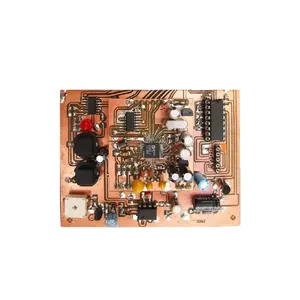

Structure of an Induction Cooking PCB Board

The structure of an induction cooking PCB board is a marvel of engineering, comprising several physical components that work in unison. At its core are the copper coils that create the electromagnetic field when energized. These are connected to a series of power transistors and capacitors that regulate the current flow. Microcontrollers are embedded within the board to manage the cooking settings, while temperature sensors provide feedback to ensure that the cooking temperature is precise and consistent. The intricate layout of these components is crucial for the efficient operation of the induction cooker.

Materials and Their Properties

The choice of materials in an induction cooking PCB board is critical for its performance. Aluminum is favored for its thermal management properties, ensuring that the board dissipates heat effectively. Plastic components are typically high-temperature resistant polymers, which provide electrical insulation to prevent short circuits. Steel is often used for its structural integrity, protecting the board from warping or damage under the stress of high temperatures. These materials are selected for their durability, conductivity, and resistance to the harsh conditions of cooking environments.

Business Usages and Applications

In the business realm, induction cooking PCB boards are integral to the operations of restaurants, catering services, and food production facilities. They are employed in appliances that require precise temperature control for consistent culinary results, such as in sous-vide cooking or chocolate tempering. The efficiency of these boards translates into energy savings and reduced operational costs, creating significant business value. Moreover, their safety features make them a preferred choice in settings where open flames would be a hazard.

Functions of Induction Cooking PCB Boards

The primary function of an induction cooking PCB board is to manage and control the electromagnetic field used for cooking. It regulates the power supplied to the coil, adjusts the cooking temperature, and times the cooking process. Advanced boards may also include functions for detecting cookware presence, preventing operation when no pot or pan is on the surface, and even adjusting the power output to match the cookware's size.

Features of Induction Cooking PCB Boards

The distinct characteristics of an induction cooking PCB board include its energy efficiency, with most of the electrical energy converted directly into heat in the cookware. They also feature precise control systems that allow for minute adjustments in temperature, which is essential for delicate cooking processes. Some boards are equipped with touch-sensitive controls, LED displays, and safety lock features, setting them apart from competitors.

Benefits of Using an Induction Cooking PCB Board

Using an induction cooking PCB board brings numerous benefits, such as improved energy efficiency, which leads to lower utility bills. The precise temperature control allows for better cooking results, and the safety aspect of the cooktop remaining cool to the touch reduces the risk of burns. Additionally, induction cooking is environmentally friendly, as it produces less ambient heat and no combustion byproducts.

How to Use an Induction Cooking PCB Board

To operate an induction cooker effectively, ensure that the cookware is induction-compatible and placed centrally on the cooking zone. Use the touch controls to set the desired power level and cooking time. For cleaning, simply wipe the cooktop with a damp cloth after use, as the surface does not get hot enough to burn spills onto it.

How to Choose the Right Induction Cooking PCB Board

Selecting the right induction cooking PCB board involves considering the size of the induction cooker, the number of cooking zones, and the specific features that are needed, such as programmable settings or smart connectivity. It is also important to consider the quality of the components and the reputation of the manufacturer.

How to Clean and Maintain an Induction Cooking PCB Board

Cleaning an induction cooking PCB board is straightforward due to the flat surface of the cooktop. Regular wiping with a suitable cleaner is sufficient for maintenance. However, it is crucial to ensure that no liquids seep into the appliance, as this could damage the PCB. For maintenance, a periodic check by a qualified technician can help to identify any potential issues before they become serious problems.

How to Install an Induction Cooking PCB Board

Installation of an induction cooking PCB board should be carried out by a professional. It involves connecting the board to the power supply and ensuring that all components are securely fitted and insulated. The installation must comply with local electrical codes and standards for safety.

Target Audience and Their Needs

The target audience for induction cooking PCB boards includes both residential and commercial users who prioritize efficiency, safety, and precision in cooking. For residential users, the ease of use and cleaning are particularly appealing, while commercial users value the durability and the cost savings associated with energy efficiency.

What are the benefits of using an induction cooking PCB board?

The benefits of using an induction cooking PCB board include improved energy efficiency, faster cooking times, and precise temperature control. Additionally, induction cooking is safer, as the cooktop remains cool to the touch, reducing the risk of burns and fires.

How does the induction cooking PCB board enhance cooking efficiency?

An induction cooking PCB board enhances cooking efficiency by directly heating the cookware, which reduces heat loss and ensures that food cooks more quickly and evenly. The PCB board's precise control allows for fine adjustments in temperature, which can lead to better cooking results.

What should be considered when installing an induction cooking PCB board?

When installing an induction cooking PCB board, it is important to ensure that the board is compatible with the induction cooker's specifications. Proper insulation and secure connections are essential for safety and performance. Additionally, the installation should be carried out by a professional to avoid any potential issues.

Discover a range of induction cooking PCB boards on Alibaba.com, designed to meet the diverse needs of the modern kitchen. Whether for residential or commercial use, these PCB boards are integral to the efficient and safe operation of induction cookers.