Popular in your industry

Related Searches:

Top categories

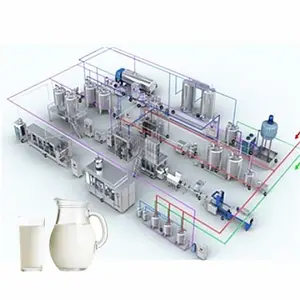

About ice popsicle production line

Introduction to Ice Popsicle Production Lines

The ice popsicle production line is a comprehensive system designed for the mass production of frozen treats. This assembly-line solution streamlines the process of making ice popsicles, from the initial mixing of ingredients to the final freezing and packaging stages. Understanding the various components and functionalities of these production lines is crucial for businesses looking to scale up their frozen dessert offerings.

Types of Ice Popsicle Machines

Within the realm of ice popsicle production, there are several machine types to consider. The freezer bowl model is a common starting point for its simplicity and ease of use, featuring a detachable bowl for pre-freezing. For more frequent production, compressor popsicle makers are advantageous due to their built-in freezing capabilities, eliminating the pre-freezing step. Lastly, the hand-crank popsicle maker remains a favorite for its rapid production capabilities, despite its more manual operation.

Key Considerations for Selection

Selecting the right popsicle manufacturing equipment involves multiple factors. Capacity is paramount when serving a large number of customers, necessitating a machine that can handle the required volume. Additionally, the ease of cleaning is a practical consideration, with models featuring removable components offering a hassle-free cleanup. It's essential to balance these factors with budgetary constraints to find a suitable solution for your production needs.

Features and Applications

Modern popsicle making machines boast features that cater to diverse applications. From adjustable molds to accommodate different popsicle sizes and shapes to automated filling and sealing mechanisms, these machines are designed to be versatile. They serve not only the food industry but also cater to businesses looking to create artisanal or custom-flavored popsicles.

Materials and Advantages

Durability and hygiene are critical in food processing, and commercial popsicle machines are built with materials that meet these requirements. Stainless steel is commonly used for its resistance to corrosion and ease of cleaning. The advantages of using a dedicated production line include consistency in product quality, increased output, and the ability to meet higher demand efficiently.

Choosing the Right Supplier on Alibaba.com

For businesses seeking to invest in an industrial popsicle maker, Alibaba.com offers a platform to connect with a variety of suppliers. The site provides access to a wide selection of production lines to suit different business sizes and production goals. By browsing the extensive catalog, buyers can compare features and find the equipment that aligns with their operational requirements.