Introduction to Frozen Fish Cutting Blades

The frozen fish cutting blade is an essential component in the food processing sector, specifically tailored for the efficient and precise cutting of frozen fish. This specialized blade is designed to operate under challenging conditions, maintaining sharpness and durability even at low temperatures.

Types and Applications

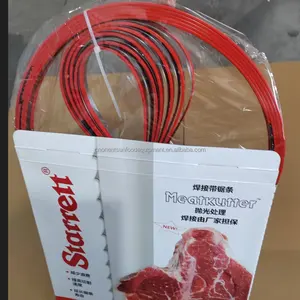

There are various types of frozen fish cutting blades, each suited for different machines and purposes. From bandsaw blades to dicer blades, the selection caters to diverse processing needs, whether for filleting, portioning, or steak cutting. These blades are integral to operations in seafood processing facilities, ensuring the seamless preparation of fish for further processing or direct sale.

Features and Materials

The construction of a frozen fish cutting blade involves materials capable of withstanding the rigors of cutting through frozen produce. Stainless steel is commonly used for its resistance to corrosion and ability to retain sharpness. The design of these blades often features serrated edges, which are crucial for cutting through icy textures without compromising the integrity of the fish.

Advantages of Using the Right Blade

Utilizing the correct frozen fish cutting blade brings efficiency and precision to food processing tasks. A blade that matches the machine's specifications and the nature of the fish can reduce waste, enhance cut quality, and increase the throughput of the processing line. Moreover, the right blade can minimize the need for frequent replacements, thereby optimizing operational costs.

Selection Considerations

When choosing a frozen fish cutting blade, it is crucial to consider the blade's compatibility with the machine and the specific type of fish to be cut. Factors such as blade thickness, tooth pitch, and material should align with the intended use to ensure optimal performance and longevity.

Maintenance and Care

Proper maintenance of a frozen fish cutting blade is vital for sustaining its performance. Regular cleaning, sharpening, and storage practices can extend the life of the blade, ensuring it remains a reliable tool in the food processing industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4