Popular in your industry

Related Searches:

Top categories

About fan aluminum extrusion

Fan Aluminum Extrusion: An Overview

Aluminum extrusions tailored for fan components are a specialized category within the broader extrusion manufacturing industry. Fan aluminum extrusion profiles are crafted to meet the precise needs of fan manufacturing, ensuring that each piece contributes to the overall functionality and efficiency of the fan. These extrusions are integral to various fan types, from industrial blowers to household cooling systems.

Design and Applications

The design versatility of aluminum extrusion for fan blades and other parts allows for a wide range of applications. These profiles are engineered to serve in construction, office furniture, interior design, and even in automotive components, showcasing their adaptability and utility in diverse fields. The application-specific shapes, such as L-angled and T-shaped bars, are meticulously produced to fit seamlessly into their intended use cases.

Material Specifications and Features

Typically, fan aluminum extrusions are manufactured from 6000 series aluminum alloys, known for their strength and corrosion resistance. The temper of these alloys can vary, usually ranging from T3 to T8, indicating the level of hardness and strength. The extrusions come in various thicknesses, catering to different structural requirements, and can be customized to meet specific design criteria.

Surface Treatment and Aesthetics

Surface treatments for aluminum fan profiles are diverse, including options like anodizing, powder coating, and wood grain finishing. Anodizing enhances the natural corrosion resistance of aluminum, while powder coating offers a durable, protective layer in a variety of colors. For a more natural look, wood grain finishes can replicate the texture and appearance of real wood, ideal for decorative purposes.

Advantages of Aluminum Extrusions in Fans

The use of aluminum extrusions in fan manufacturing brings several advantages. These include the material's lightweight nature, which contributes to the ease of installation and handling. Additionally, the thermal conductivity of aluminum is beneficial in applications where heat dissipation is crucial, such as in cooling systems. The durability and resistance to corrosion also ensure a longer lifespan for the fan components.

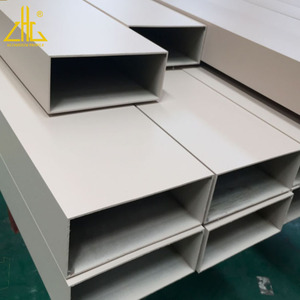

Customization and Variety

Customization is a key aspect of fan aluminum extrusion production. Suppliers on Alibaba.com can tailor the profiles to specific dimensions and surface finishes, ensuring that the product meets the exact needs of buyers. The variety of available shapes, such as hollow tubes and channels, allows for a broad spectrum of design possibilities and functional applications.