Exploring Electric Stove Moulds

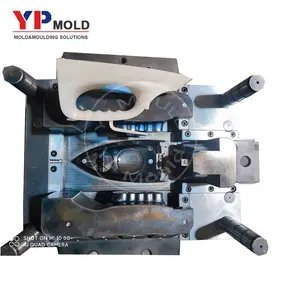

The realm of manufacturing is vast, and within it, the electric stove mould plays a pivotal role in shaping appliances that are integral to modern kitchens. Moulds for electric stoves are specialized frameworks designed to cast parts of electric stoves, ensuring precision and consistency in production.

Types and Applications

Electric stove moulds come in various types, each tailored for different components and stove models. From intricate burner moulds to larger structural components, these moulds are essential for creating durable and reliable electric stove parts. Their applications span across the manufacturing of electric stove tops, control knobs, and support frames, highlighting their versatility in the appliance manufacturing industry.

Material Insights

The materials used in the production of moulds for electric stoves are chosen for their durability and heat resistance. Iron is a commonly used material, offering longevity and sturdiness. Other materials include aluminum and steel, which are selected based on the specific requirements of the moulding process and the end-use of the electric stove parts.

Features and Advantages

A well-crafted electric stove injection mould brings numerous advantages to the manufacturing process. These moulds are designed for repeatability, ensuring each part produced is identical to the last, which is crucial for mass production. The use of standardized components like lift bars and clamp slots can further streamline the manufacturing process, enhancing efficiency and reducing costs.

Choosing the Right Mould

Selecting the appropriate electric stove mould design is a critical decision that impacts the final product's quality. Factors to consider include the mould's material, the complexity of the design, and the expected production volume. Suppliers on Alibaba.com offer a range of options, and collaboration with these experts can lead to a mould that meets the specific needs of the production line.

Optimizing Production with Moulds

Investing in a quality electric stove mould manufacturer can significantly optimize production. Standardization of mould parts not only simplifies the manufacturing process but also aids in maintaining consistency across various product lines. This strategic approach to mould design can be a game-changer for businesses looking to enhance their production efficiency.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4