Popular in your industry

Related Searches:

Top categories

About diesel melting furnace for aluminum

Introduction to Diesel Melting Furnaces for Aluminum

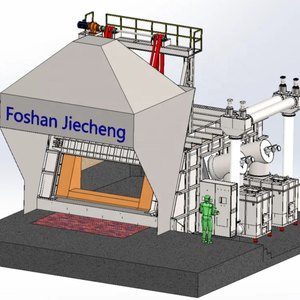

Diesel melting furnaces for aluminum are specialized industrial equipment designed for the high-temperature processing of various metals, particularly aluminum. These robust machines are integral to the metallurgical industry, facilitating the transformation of raw metal into usable forms through the melting process.

Types and Applications

The versatility of diesel melting furnaces for aluminum is evident in their various types and applications. They are primarily utilized for melting scrap metals, including iron, copper, and predominantly aluminum. The smaller variants cater to precious metals like gold and silver, while larger models handle substantial quantities, capable of processing up to 20 tons of material.

Technical Features and Materials

Constructed to withstand extreme conditions, these furnaces operate within a power input range of 380v to 950v and a working power spectrum from 180kw to 2,000kw. The materials used in their construction are chosen for durability and heat resistance, ensuring a long service life under intense operational demands. Large capacitor banks are incorporated to stabilize the electric current, with excellent insulation to prevent any water-induced faults.

Operational Advantages

The operational efficiency of a diesel melting furnace for aluminum is a significant advantage. Melting times vary by metal type and furnace capacity, typically ranging from 40 to 60 minutes. Advanced cooling systems, including water-cooling mechanisms, are in place to manage the high temperatures, which can reach between 1,750 to 2,100 degrees Celsius. Additionally, the tilting capability of melting pots, often up to 95 degrees, ensures complete and controlled pouring of molten metal.

Safety and Control Systems

Safety is paramount in the design of diesel melting furnaces for aluminum. Built-in safety systems, such as circuit breakers, are standard to mitigate any operational hazards. Furthermore, the integration of a PLC system streamlines the operation, providing a user-friendly interface for monitoring and controlling the melting process.

Induction and Hydraulic Systems

The majority of diesel melting furnaces for aluminum leverage electrical induction heating systems for efficient melting. The use of hydraulic pressure systems is also common, offering the necessary tilting force to the furnace pot for handling the molten metal. This combination of advanced technologies ensures a seamless and effective melting process.

In conclusion, for those in the market for an industrial-grade diesel melting furnace for aluminum, a diverse array of options awaits. With a focus on operational efficiency, safety, and advanced control systems, these furnaces are engineered to meet the rigorous demands of metal processing industries.