Diamond Powder: Essential for Cutting Tools

The realm of industrial cutting tools is incomplete without the mention of diamond powder for cutting tool applications. This fine abrasive is integral in the manufacturing and maintenance of cutting instruments across various sectors, including technology, domestic, and industrial domains. The versatility of diamond powder lies in its exceptional hardness and cutting efficiency, making it a staple for professionals seeking precision and durability in their tools.

Understanding Diamond Powder Applications

The application of diamond abrasive powder extends beyond mere cutting. It is a critical component in processes such as grinding, polishing, and lapping. The powder is used to produce a high-quality finish on various surfaces, ensuring that tools operate at their peak performance. Its usage in drilling and honing applications underscores its importance in creating and maintaining the sharpness and functionality of cutting tools.

Features and Materials of Diamond Powder

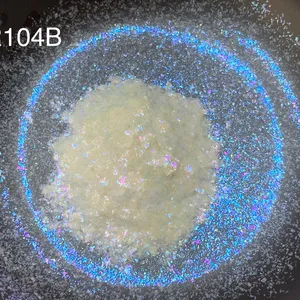

Diamond powder is derived from both natural and synthetic sources, ensuring a range of options for specific applications. The material's innate hardness is harnessed to create an abrasive that can withstand extreme conditions without compromising its efficacy. The powder is characterized by its grain size, which can be tailored to the needs of the task at hand, from coarse grains for substantial material removal to fine grains for a polished finish.

Advantages of Diamond Powder in Tool Fabrication

In the fabrication of cutting tools, the use of synthetic diamond powder offers numerous advantages. Its uniform particle size allows for consistent performance, while the material's durability leads to longer tool life and reduced downtime. The adaptability of diamond powder to various bonding methods makes it an ideal choice for creating a wide range of abrasive tools, from diamond plates to sanding blocks.

Selection Criteria for Diamond Powder

Choosing the right industrial diamond powder involves considering factors such as hardness, grit size, and the intended application. The powder must be compatible with the bonding agent used in the tool's manufacture and should be selected based on the desired outcome, whether it is for a smooth finish or rapid material removal. The physical properties of the diamond powder, such as its thermal stability and resistance to wear, also play a crucial role in its effectiveness as an abrasive.

Procuring Diamond Powder on Alibaba.com

Professionals seeking quality diamond powder for cutting tools will find a comprehensive selection on Alibaba.com. The platform facilitates the connection between buyers and reputable suppliers, offering a variety of diamond powder options to suit diverse industrial needs. Without endorsing specific brands or making absolute claims, Alibaba.com serves as a gateway to a wide array of diamond powder products, ensuring that buyers can make informed decisions based on their specific requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4