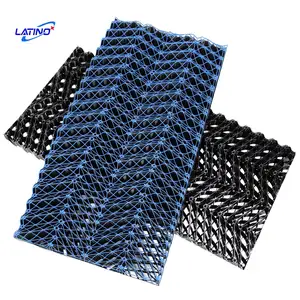

A cooling tower has several parts that enable it to operate efficiently. These include fans, spray nozzles, distribution, and collection basins. A fan is an essential part of any customer fills. It helps in creating and guiding airflow through the heated water by either pushing or drawing it. Another essential part of it is the spray nozzle. It helps in increasing the water’s surface area by ensuring that the water droplets are evenly distributed across the fill for air contact. The distribution basin is also a fundamental part of a customer fills in a crossflow cooling system, and it acts like the spray nozzle. It is mounted at the top of the tower for even distribution of hot water.

There are various types of cooling towers available including crossflow, counterflow, and hyperbolic. When it comes to a crossflow cooling tower, the air utilized in the cooling process flows through the heated water horizontally through the spills. During this process, water flows from the tower’s distribution basin due to gravity forces. The cool air and heated water enter it from opposite directions for the counterflow cooling tower. However, the air flows vertically through the splash fills from the bottom of the tower. This customer fills cannot employ the gravity flow since air flows upwards. Lastly, hyperbolic cooling systems are well-designed and utilize very few resources. Nevertheless, they are capable of efficiently managing large-scale operations within major power plants.

For a wholesale customer fills, visit Alibaba.com. This platform has a wide variety of cooling towers, and so you can be sure to find one that suits your needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4