Popular in your industry

Top categories

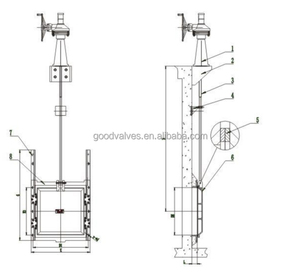

About channel sluice gate

Understanding Channel Sluice Gates in Mineral Separation

Channel sluice gates are integral components in the realm of mineral separation, playing a pivotal role in the refinement and extraction of valuable minerals from mining spoil. These devices are designed to facilitate the segregation of materials such as gold, bauxite, iron, and rare earth metals, which are otherwise challenging to isolate using conventional methods.

Types of Mineral Separators Incorporating Channel Sluice Gates

The application of channel sluice gates spans across various types of mineral separators. One common type is the electrostatic mineral separation tool, which employs charged particle beams to differentiate between ore and rock particles. Another prevalent style is the high tension roller, or electrodynamic separator, which utilizes rotating drums to process finer materials with greater precision. Both types are available in static models for fixed-site processing and portable designs for field deployment near mining sites.

Applications and Features of Channel Sluice Gates

Channel sluice gates are versatile in their applications, ranging from aiding in the extraction process of metallic ores to the separation of minerals from beach sand. The features of these gates are tailored to support various separation techniques, including vibrating shaker tables and alluvial washing machines. These gates are not only instrumental in conjunction with other precise separation tools but also efficient when used independently in less demanding accuracy scenarios.

Materials and Advantages of Channel Sluice Gates

Constructed to withstand the rigors of mineral processing, channel sluice gates are made from robust materials capable of enduring the abrasive nature of mining spoils. The advantages of using these gates include enhanced efficiency in mineral separation and the ability to handle a wide range of materials, from coarse to fine particulates, thereby optimizing the overall extraction process.

Choosing the Right Channel Sluice Gate

Selecting the appropriate channel sluice gate is crucial for any mineral separation task. Factors to consider include the specific mineral to be extracted, the granularity of the material, and the desired level of precision. While browsing the extensive listings on Alibaba, buyers can find a variety of sluice gate options to meet their operational needs without the concern of overpromising outcomes.

Integration with Mineral Processing Systems

Incorporating a channel sluice gate into an existing mineral processing system can significantly enhance the separation efficiency. These gates are designed to integrate seamlessly with various types of mineral separators, ensuring a smooth operation flow and improved yield of valuable minerals from processed spoil.