Introduction to Boot Making Machines

The craft of boot making has evolved significantly with the advent of modern machinery. A boot making machine is a cornerstone in the footwear industry, enabling the mass production of boots with precision and efficiency. This category encompasses a variety of machines designed for different stages of the boot making process, from initial cutting to final stitching.

Types of Boot Making Machinery

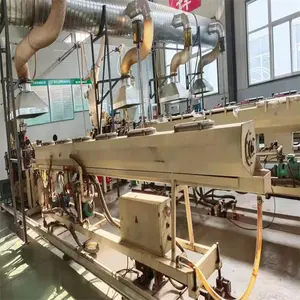

Within the realm of boot fabrication, several types of machinery play pivotal roles. The boot making sewing machine is integral for assembling various parts of the boot with durable seams. Cutting machines, on the other hand, are used to accurately shape the leather or fabric before assembly. Advanced boot making setups may also include specialized machinery for tasks such as sole attachment and finishing.

Applications and Features

Boot making machines are not limited to a single function; they offer a range of applications. For instance, embroidery machines within this category can embellish boots with intricate designs, while heavy-duty machines focus on the structural assembly of the footwear. Features of these machines vary, with some offering automated operations to enhance production speed and consistency.

Materials and Advantages

The construction of a boot making machine typically involves robust materials capable of withstanding the rigors of shoe production. The advantages of utilizing such machinery include increased output, uniform product quality, and the ability to work with a diverse array of materials, from traditional leather to modern synthetics.

Choosing the Right Machine

Selecting the appropriate boot making machine requires consideration of the workshop size and the specific boot production needs. It is essential to ensure that the chosen machine fits well within the operational space, allowing for an efficient workflow. Prospective buyers should utilize the filtering functions available to identify machines that match their specific requirements in terms of size, function, and capacity.

Integrating Complementary Machinery

In addition to the primary boot making equipment, integrating complementary machinery such as a boot making sewing machine can further enhance the production line. These additional machines can provide supplementary detailing and finishing touches that distinguish high-quality boots.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4