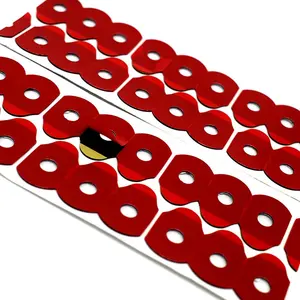

Introduction to Blocking Pads

Blocking pads are essential components in the eyewear industry, serving as a critical interface between the lens and the processing equipment during the edging process. These pads prevent slippage and protect the lens surface from scratches or damage, ensuring precision and care in lens fitting.

Types and Applications

There are various types of blocking pads tailored to different eyewear materials and designs. From standard adhesive pads for general use to specialized hydrophobic pads for coated lenses, the selection is vast. These items are not only used in the optical lab but also find applications in retail settings for minor adjustments and repairs.

Features and Materials

The effectiveness of blocking pads lies in their features. Typically, they boast a strong adhesive backing that adheres to the lens during the cutting process. The materials range from foam to rubber composites, designed to accommodate the diverse needs of lens types, from single-vision to progressive lenses.

Advantages of Quality Blocking Pads

Quality blocking pads offer numerous advantages, such as enhanced grip strength, residue-free removal, and compatibility with various lens treatments. They are pivotal in maintaining the integrity of high-precision lens cutting and edging, a testament to their indispensable role in eyewear manufacturing and maintenance.

Selection Considerations

When choosing blocking pads, factors such as the pad's thickness, material composition, and adhesive strength are crucial. It's important to select the appropriate pad for the specific lens material and the type of edging equipment used.

Complementary Products

In addition to blocking pads, other complementary products like lens cleaning solutions, microfiber cloths, and protective cases play a supportive role in the eyewear industry, ensuring lenses are not only accurately cut but also maintained in pristine condition post-production.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4