Top categories

Energy Chemicals

Flavor & Fragrance

Chemical Reagents

Non-Explosive Demolition Agents

Other Chemicals

Custom Chemical Services

Biological Chemical Products

Painting & Coating

Surface Treatment Chemicals

Catalysts & Chemical Auxiliary Agents

Admixture & Additives

Pigments & Dyestuff

Basic Organic Chemicals

Agrochemicals

Inorganic Chemicals

Coating & Paint

About products and suppliers

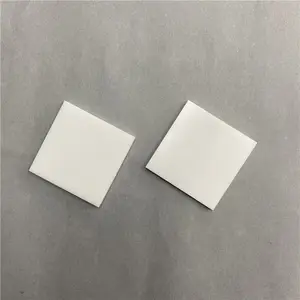

Introduction to Beryllium Oxide Plate Substrates

Beryllium oxide plate substrates represent a specialized category of advanced ceramic materials known for their unique combination of thermal, electrical, and mechanical properties. These substrates are crafted from beryllium oxide (BeO), which is a white crystalline oxide of beryllium with a high melting point and exceptional thermal conductivity.

Properties and Applications

The intrinsic properties of beryllium oxide ceramics make them suitable for a range of applications, particularly where high thermal conductivity and electrical insulation are required. These substrates are often utilized in electronics, serving as crucial components in transistors, diodes, and integrated circuits. Their ability to effectively dissipate heat while insulating electricity makes them invaluable in high-power devices or systems exposed to significant thermal loads.

Types and Features

Beryllium oxide substrates come in various grades and purities, tailored to meet the demands of different industrial applications. The features of these substrates include high thermal conductivity, which rivals that of some metals, and excellent dielectric strength. They also exhibit a low coefficient of thermal expansion, which ensures dimensional stability under temperature fluctuations, making them ideal for critical electronic applications.

Material Advantages

The advantages of using beryllium oxide ceramic substrates are manifold. Their high thermal conductivity aids in the efficient cooling of electronic components, thereby enhancing performance and longevity. The material's robustness in the face of thermal cycling reduces the risk of material failure, which is crucial in high-stakes industries such as aerospace and defense. Additionally, the strong dielectric properties allow for the miniaturization of components without sacrificing performance.

Manufacturing and Customization

Manufacturers of ceramic substrates offer a range of customization options to fit specific industrial needs. While standard sizes and shapes are readily available, custom dimensions and finishes can be produced to meet precise specifications. The manufacturing process of beryllium oxide plate substrates involves sophisticated techniques to ensure the material's purity and structural integrity, which is essential for its high-performance characteristics.

Environmental and Safety Considerations

While beryllium oxide is known for its superior properties, handling and processing require adherence to safety protocols due to the toxicity of beryllium dust. Suppliers and users must ensure proper safety measures are in place to mitigate any health risks associated with the material. Environmental considerations are also taken into account during the manufacturing and disposal of these ceramic substrates to minimize ecological impact.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4