Introduction to Automatic Small Surface Grinding Machines

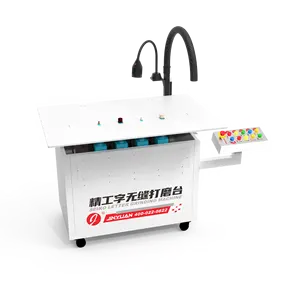

Surface grinding machines are essential tools in the field of metalworking, enabling precision work on the smallest of components. The automatic small surface grinding machine category encompasses a range of machines designed for the automated surface finishing of various materials. These compact units are engineered to perform intricate grinding tasks in manufacturing plants, machinery repair shops, and material shops, among other industrial settings.

Types and Applications

The versatility of small surface grinders is evident in their various types, each suited to specific applications. From flat surfaces to complex shapes, these machines cater to a multitude of grinding tasks. The adaptability of these machines allows for their use in diverse industries, from metal fabrication to precision engineering, contributing to their widespread adoption in markets such as Mexico, Russia, and Colombia.

Features and Materials

An automatic surface grinder is equipped with features that promote efficiency and precision. Components like motors, bearings, and engines are integral to their operation, ensuring smooth performance. The construction materials of these machines are selected for durability and performance, ensuring they can withstand the rigors of industrial use while maintaining accuracy in grinding tasks.

Advantages of Automation in Grinding

Automation in surface grinding equipment brings numerous advantages to the production process. The automated nature of these machines means they can operate with minimal human intervention, leading to consistent results and increased productivity. Features such as competitive pricing and ease of operation make these machines an attractive investment for businesses looking to optimize their grinding processes.

Choosing the Right Machine

Selecting the right automatic grinding machine involves considering the specific requirements of the task at hand. Factors such as the material to be ground, the desired finish, and the production volume all play a role in determining the most suitable machine. With a range of options available, it is crucial to assess the features of each machine to find the one that aligns with your operational needs.

Conclusion

In conclusion, the automatic small surface grinding machine is a key piece of equipment for industries requiring precise surface finishing. Its automated capabilities, combined with a variety of types and features, make it a valuable asset for businesses looking to enhance their production quality and efficiency.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4