Popular in your industry

Related Searches:

Top categories

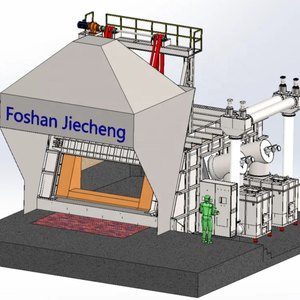

About aluminium recycling furnace

Introduction to Aluminium Recycling Furnaces

The aluminium recycling furnace is a pivotal component in the metal recycling industry, designed to repurpose scrap into reusable material. This category encompasses a variety of systems tailored to process aluminum efficiently, ensuring a sustainable approach to metal manufacturing.

Types and Applications

Diverse in type, aluminum recycling furnaces cater to different scales of operation. From rotary furnace aluminium recycling units, which are adept at handling large quantities of scrap, to smaller, stationary furnaces for more precise melting, the range is extensive. These furnaces serve crucial roles in various sectors, including automotive, construction, and packaging, where recycled aluminum is in high demand.

Features and Materials

Constructed to withstand high temperatures, aluminium recycling furnaces are made from robust materials that can endure the intense heat required to melt aluminum. Features such as tilting mechanisms, often powered by hydraulic systems, facilitate the handling of molten metal. The incorporation of advanced insulation materials and cooling systems, like water-cooling, is standard to ensure safety and efficiency.

Advantages of Recycling Furnaces

The use of an aluminum recycling furnace presents numerous advantages. It promotes energy conservation by requiring less power compared to primary production and aids in reducing the environmental impact by minimizing waste. Additionally, the recycling process within these furnaces is a testament to the versatility of aluminum, as it can be recycled without degradation of its inherent properties.

Operational Features

Modern aluminium recycling furnaces are equipped with PLC systems for operational control, ensuring precision and safety. The melting process can be conducted in either open or enclosed systems, with temperatures typically ranging from 1,750 to 2,100 degrees Celsius. Safety features like circuit breakers are integral to these systems, providing automatic shutdown in case of faults.

Choosing the Right Furnace

Selecting the appropriate aluminum recycling furnace is crucial for any operation. Factors such as melting speed, which can vary from 40 to 60 minutes, and the capacity of the furnace, are important considerations. The ability to tilt the melting pot, sometimes up to 95 degrees, is also a key feature that enhances the functionality of the furnace.