Popular in your industry

Related Searches:

Top categories

About 6 inch pipe threading machine

Introduction to 6 Inch Pipe Threading Machines

The realm of pipe fabrication is incomplete without the mention of 6 inch pipe threading machines. These machines serve as a cornerstone for threading operations, a process crucial for joining pipes securely in various industrial applications. The category encompasses a range of devices designed to create threads on the interior or exterior of a pipe, facilitating a tight and leak-proof connection.

Types and Applications

There exists a spectrum of pipe threading equipment, each tailored to specific requirements. From manual threading tools to fully automated systems, the selection is vast. The 6 inch variant is particularly versatile, accommodating a range of pipe diameters, and is commonly employed in water pipe construction, oil and gas pipelines, and infrastructure projects.

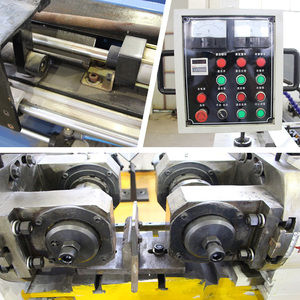

Features and Materials

A pipe threader machine is typically constructed from hardened materials to withstand the rigors of cutting threads into metal pipes. The inclusion of carbon steel or cast iron components ensures durability and longevity. Advanced models boast features such as automatic thread size selection, built-in cutters, and footswitch operation for enhanced efficiency and user safety.

Advantages of Modern Threading Machines

Modern pipe threading machines are engineered for precision and ease of use. Their ability to produce consistent threads across multiple pipe fittings reduces material wastage and increases the reliability of pipe installations. Furthermore, the integration of eco-friendly technology minimizes environmental impact, while energy-efficient designs contribute to reduced operational costs.

Operational Sustainability and Maintenance

Sustainability is a key factor in the design of current threading machines. With an emphasis on energy efficiency, these machines not only lower electricity consumption but also offer temperature resistance, reducing the frequency of maintenance. Anti-corrosive and anti-rust features further enhance the machine's operational life, ensuring that they remain a mainstay in industrial settings for years.

Choosing the Right Machine

Selecting the right 6 inch pipe threading machine involves considering various functionalities and capacities. While automatic versions streamline the threading process, semi-automatic models provide a balance between control and efficiency. It is essential to assess the specific requirements of your projects to determine the most suitable machine type, ensuring seamless integration into your workflow.