Introduction to Wood Trimmer Machines

Wood trimmer machines are essential tools for precision woodworking, offering versatility and efficiency in various applications. These machines are designed to trim and shape wood with accuracy, making them indispensable in both professional carpentry and DIY projects.

Types and Features

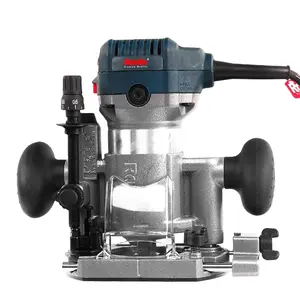

Electric wood trimmers are popular for their ease of use and consistent power supply, while cordless models offer portability and convenience free from the constraints of a power cord. Handheld wood trimmers provide maneuverability for intricate work, and benchtop versions ensure stability for larger tasks. Features such as adjustable speed settings, ergonomic designs, and dust collection systems enhance the user experience and efficiency of the task at hand.

Applications and Versatility

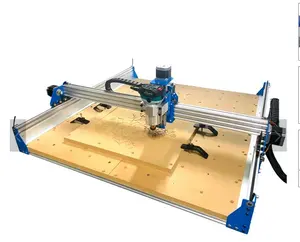

The application of wood trimmer machines spans across creating joints, edging, making cut-outs, and intricate wood shaping. They are a staple in cabinetry, furniture making, and decorative woodworking. Their adaptability allows for both fine-detail work and bulk material removal, showcasing their versatility in various project scales.

Materials and Durability

Constructed from durable materials such as hardened plastics and metals, wood trimmer machines are built to withstand the rigors of woodworking. The use of carbide-tipped blades in many models ensures long-lasting sharpness and precision, while the robust build minimizes vibrations for smoother operation.

Advantages and Maintenance

The advantages of using a wood trimmer machine include increased productivity, consistent results, and the ability to achieve complex designs with relative ease. Maintenance aspects like replaceable parts and easy-to-clean designs ensure that these machines remain reliable over time, with minimal downtime for repairs.

Choosing the Right Machine

Selecting the right wood trimmer machine involves considering the specific needs of your project, such as the material thickness, precision required, and the frequency of use. Features like water-resistant construction and quiet operation cater to specialized environments, while options for manual or automatic operation provide flexibility for various woodworking demands.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4