Introduction to Corn Snack Production Lines

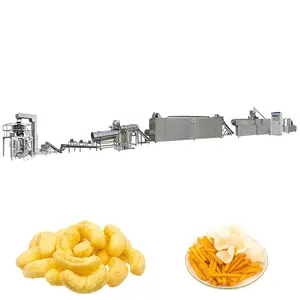

The corn snack production line is an assembly of sophisticated machinery designed to create a variety of corn-based snacks. This comprehensive system streamlines the process of snack production, from raw material handling to the final packaging stage. The versatility of these production lines allows manufacturers to produce a range of products, including corn chips and corn puffs, catering to diverse consumer tastes and preferences.

Types and Applications

There are several types of corn snack production lines, each tailored to produce specific snack varieties. The corn chips production line is engineered to produce crispy, flat snacks, while the corn puff production line focuses on lighter, airier snacks that are extruded and then baked or fried. These snacks are ubiquitous in the market, found in convenience stores, supermarkets, and vending machines, serving as quick, on-the-go options for consumers worldwide.

Features and Materials

A corn snack production line typically features robust construction with stainless steel components, ensuring durability and compliance with food safety standards. The machinery is equipped with advanced technology for extrusion, cutting, baking, and flavoring, which are integral to producing consistent and high-quality snacks. The materials used are chosen for their resistance to corrosion, ease of cleaning, and longevity, which are crucial for maintaining the efficiency of the production process.

Advantages of the Production Line

Investing in a corn snack production line brings several advantages. The automation of the line allows for continuous, efficient production with minimal manual intervention, leading to a consistent output. This automation also enables quick and easy product changeovers, allowing manufacturers to respond swiftly to changing market trends. Furthermore, the production line's design typically allows for scalability, making it suitable for businesses of varying sizes.

Considerations Before Purchase

When considering the acquisition of a corn snack production line, factors such as the line's capacity, compatibility with existing operations, and the footprint should be evaluated. The user-friendliness of the system is also paramount, as it facilitates a smoother operation and can potentially reduce training time. Prospective buyers should assess the production line's adaptability to different recipes and snack types, ensuring the ability to diversify product offerings.

Choosing the Right Production Line on Alibaba.com

Selecting the appropriate corn snack production line on Alibaba.com involves comparing the features of various models to find the one that aligns with your production requirements. The platform's extensive assortment allows for a thorough evaluation of the specifications and capabilities of each line. With a focus on facilitating connections between buyers and suppliers, Alibaba.com streamlines the process of sourcing the right machinery for your snack production needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4