Top categories

Energy Chemicals

Flavor & Fragrance

Chemical Reagents

Non-Explosive Demolition Agents

Other Chemicals

Custom Chemical Services

Biological Chemical Products

Painting & Coating

Surface Treatment Chemicals

Catalysts & Chemical Auxiliary Agents

Admixture & Additives

Pigments & Dyestuff

Basic Organic Chemicals

Agrochemicals

Inorganic Chemicals

Coating & Paint

About products and suppliers

Understanding Edge Banding Hot Melt Glue

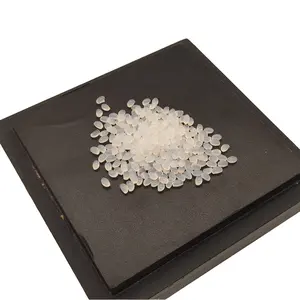

Edge banding hot melt glue is a specialized adhesive used primarily in the woodworking and furniture manufacturing industries. This thermoplastic adhesive is designed for quick bonding and strong hold, making it an essential component in the edge banding process. Edge banding, a method used to cover the raw edges of wood panels with veneer or plastic, relies on the consistent performance of hot melt glue for edge banding to ensure a seamless finish.

Types and Applications

The variety of edge banding glue pellets and adhesives cater to different machinery and materials. Users can select from edgebander glue pellets, which are melted and applied via edge banding machines, or opt for cartridges and bulk systems depending on their operational scale. These adhesives are not just limited to wood panels but are also used for veneers, plastics, and other edge banding materials in both commercial and residential furniture production.

Features and Materials

Hot melt adhesive for edge banding is formulated to offer quick adhesion, reducing the time needed for bonding edges. The composition typically includes a mix of ethylene-vinyl acetate (EVA), polyolefins, or polyamides, depending on the required bonding strength and flexibility. The choice of material affects the melting point, open time, and viscosity of the glue, which are critical factors in the edge banding process.

Advantages of Using Quality Edge Banding Adhesives

Using a reliable edge banding machine glue ensures a durable bond that can withstand handling and environmental factors. High-performance adhesives like jowat edge banding glue provide excellent adhesion and are suitable for a range of temperatures, which is crucial for products that undergo thermal changes during shipping or use.

Selection Criteria for Edge Banding Hot Melt Glue

When choosing the right hot melt glue for edge banding machine, consider the substrate compatibility, bonding time, and the specific requirements of the edge banding process. It's important to select an adhesive that not only provides a strong bond but also maintains the aesthetic quality of the finished product. The market offers a spectrum of edgebanding hot melt adhesive options, each designed to meet different industry standards and manufacturing needs.

Conclusion

The use of hot melt edge banding machine and the corresponding adhesives is integral to achieving a high-quality finish in furniture production. With a comprehensive selection of edgebanding hot melt products available on Alibaba.com, businesses can find the right adhesive to meet their production needs without compromising on quality or efficiency.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4