Exploring 12-Volt DC Motors

Electric motors that operate on a 12-volt direct current are engineered to function with a 12-volt power supply. These motors are ubiquitous across a myriad of applications, from domestic gadgets to electric bicycles, and are integral to the automation of smart homes. The principal function of a DC motor is the transformation of electrical energy into mechanical energy, a critical process for any device that needs to move or execute an action.

12-volt DC motors are particularly prized for their operational efficiency, dependability, and seamless integration with established systems. Such motors are integral to a range of products, including portable power tools, devices powered by solar energy, and vehicles like electric scooters and golf carts. Their mechanism relies on generating a magnetic field inside the motor. An electric current traverses the wire coil wrapped around the motor's stator—the non-moving part—creating a magnetic field. This current, typically regulated by an external power source like a battery, prompts the rotor—the moving part—to spin, thereby producing motion.

The advantages of employing a 12-volt motor include reduced operational costs due to the motor's efficiency and the convenience of powering several devices from a single 12-volt source. Moreover, these motors are often more compact and lighter than their high-voltage counterparts, facilitating installation in areas where space is at a premium.

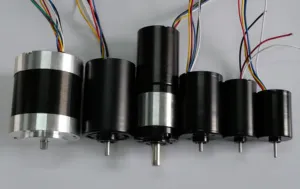

Varieties of 12-Volt DC Motors

Different electrical configurations are available in DC motors to cater to a range of applications. Below are some prevalent types:

-

Brushed DC Motor: A ubiquitous variant in domestic appliances and power tools, these motors have a rotor with windings that make contact with brushes to transmit current. The continuous contact between the brushes and the rotor enables efficient energy transfer but also leads to brush wear and friction over time.

-

Brushless DC Motor: Known as BLDC motors, these variants lack brushes, obviating the need for frequent replacements. They are commonly found in portable power tools, electric bicycles, and smart home gadgets where reliability is paramount.

-

Series Wound Motor: These motors feature a coil wound on a core that rotates within a magnetic field. Their robustness allows them to manage high torque demands, making them apt for heavy-duty uses such as industrial equipment and electric vehicles.

-

Shunt Wound Motor: These are akin to series wound motors but include a parallel shunt circuit. They provide precise speed control and are typically used in scenarios that demand stable operation, such as in consumer electronics or automotive applications.

Selecting a 12-Volt DC Motor

Choosing the appropriate 12-volt DC motor requires consideration of several key factors:

-

Motor Type: Decide between brushed and brushless motors based on your performance needs and the sensitivity of the application. Brushed motors are more cost-effective for straightforward tasks, while brushless motors offer enhanced efficiency and longevity for more rigorous demands.

-

Construction: The motor's build—be it permanent magnet, series wound, or shunt wound—will influence its performance traits, such as torque ripple and speed stability.

-

Protection Feature: Motors may need special protective features like explosion-proof or IP54 ratings for resistance to dust and water, depending on their intended environment.

-

Phase Requirement: Verify that the motor's phase requirement aligns with your power supply; single-phase motors are widely used and fit most applications, while three-phase motors are sometimes necessary for more substantial power needs.

-

Application & Industry: Reflect on the motor's intended use. For instance, domestic appliances may benefit from quieter motors, whereas industrial settings might prioritize durability and consistent performance.

On Alibaba.com’s B2B marketplace, consider vendors that provide custom support options like ODM or OBM if off-the-shelf solutions do not align with your specific requirements.

About 12-Volt DC Motors on Alibaba.com

Alibaba.com is a premier marketplace for businesses in search of dependable 12-volt DC motors, offering a vast selection from global suppliers. The platform's commitment to international trade is underscored by its intuitive interface, which accommodates local languages and is optimized for mobile use, ensuring businesses can source products with ease, irrespective of their geographic or operational scale.

Alibaba.com furnishes comprehensive product details and vendor profiles, aiding buyers in making well-informed choices suited to their particular demands. The Trade Assurance service adds a layer of security by safeguarding payments until delivery is confirmed. These features reflect Alibaba.com's dedication to quality and customer satisfaction, positioning it as a prime source for 12-volt DC motors.

Opting for Alibaba.com as your procurement platform grants access to a diverse product range and a robust system that simplifies the purchasing process. This enables you to concentrate on your business's unique needs while ensuring that your acquisitions, whether in bulk or as single units for pricier commercial items, are of investment quality. With its extensive support network and commitment to making global trade straightforward, Alibaba.com equips businesses to flourish in any market by providing the necessary tools for growth and success.

Frequently Asked Questions About 12-Volt DC Motors

What is the primary benefit of a 12-volt DC motor?

12-volt DC motors are optimized for low power consumption, rendering them ideal for battery-operated devices or systems where energy efficiency is paramount.

How do DC motors compare to AC motors in terms of functionality?

DC motors are favored in scenarios that demand precise speed control and consistent torque, while AC motors are more suitable for applications with fixed-speed requirements and higher power demands.

Are DC motors suitable for dusty or moist environments?

Certain DC motors are equipped with protective features like totally enclosed or drip-proof designs, enabling them to function in environments laden with dust or moisture.

What considerations are important when selecting a DC motor for a domestic appliance?

In choosing a DC motor for a domestic appliance, it is crucial to consider the necessary power, speed, and torque, as well as size constraints and operating voltage to ensure compatibility.

How does a DC motor's construction affect its performance?

A DC motor's build, whether it's a permanent magnet, series wound, or shunt wound, impacts its efficiency, speed, and torque. Permanent magnet motors are highly efficient with good power density, while shunt wound motors offer consistent torque, making them suitable for applications that require uniform performance across various speeds.

What do 'brushed' and 'brushless' signify in DC motors?

Brushed DC motors utilize brushes and a commutator to manage current within the motor's magnetic field, whereas brushless DC motors employ a permanent magnet and an external commutator, leading to reduced friction and wear, thus lower maintenance and greater efficiency.

Can DC motors operate at voltages other than 12 volts?

DC motors are available for a range of voltages beyond 12 volts. It is essential to select a motor rated for the specific voltage at which it will be used to ensure safety and optimal performance.

How can I determine if a DC motor is compatible with a variable frequency drive (VFD)?

To be VFD-compatible, a DC motor must be either a brushless DC motor (BLDC) or a permanent magnet synchronous motor (PMSM), as these types are engineered to work effectively with the variable speeds and torques provided by VFDs.

Is it possible to obtain a custom DC motor for a particular application?

Many suppliers offer customization services, including ODM (Original Design Manufacturing) and OBM (Original Brand Manufacturing), enabling businesses to adapt DC motors to their specific needs and applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4