Popular in your industry

Related Searches:

About zinc coating thickness gauge

Zinc Coating Thickness Gauge: An Essential Tool for Quality Assurance

The zinc coating thickness gauge is an indispensable instrument for professionals in the metal finishing industry. This device is specifically designed to measure the thickness of zinc layers applied to metal surfaces, ensuring that the galvanization process meets the required standards for durability and corrosion resistance. Accurate measurement is crucial for the longevity and quality of the coated product.

Understanding the Types and Applications

There are various types of gauges available, such as the zinc plating thickness tester and the galvanized coating thickness gauge. Each serves a specific purpose, from simple handheld devices for on-site measurements to more sophisticated laboratory equipment for detailed analysis. These tools are widely used in industries where protective coatings are essential, including automotive, construction, and marine engineering.

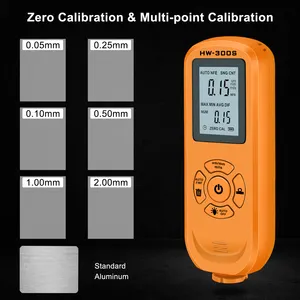

Features and Materials of Zinc Coating Thickness Gauges

A zinc coating thickness measuring instrument is typically crafted from durable materials capable of withstanding industrial environments. Many gauges are equipped with digital displays for easy reading and may include features such as automatic substrate recognition and data storage. The precision of these instruments is paramount, with some capable of detecting thicknesses down to micrometer levels.

Advantages of Using a Zinc Thickness Tester

Utilizing a zinc coating thickness tester offers numerous advantages. It provides immediate feedback on the coating process, allowing for quick adjustments to ensure compliance with specifications. This not only saves time but also reduces material waste. Moreover, consistent use of a zinc coating thickness meter helps maintain quality control throughout the production cycle.

Selecting the Right Gauge for Your Needs

When choosing a gauge, it is important to consider the specific requirements of your application. For instance, an elcometer for zinc coating is a popular choice for its robustness and accuracy. Factors such as measurement range, data output options, and environmental resistance should be taken into account to ensure that the selected gauge meets the demands of the task at hand.

Integrating Zinc Coating Measurement into Quality Control

Incorporating a galvanising thickness tester into your quality control procedures can significantly enhance the integrity of your products. By ensuring that the zinc plating meets industry standards, you can avoid the costly repercussions of coating failures and elevate the overall quality of your metal products.

Selecting the appropriate zinc coating thickness gauge is essential for any business that relies on galvanized metals. Alibaba.com offers a platform where a variety of gauges can be compared and sourced to meet your specific needs, without the hassle of navigating through unrelated products. By choosing the right measurement tool, businesses can uphold their commitment to quality and durability in their metal coatings.