Introduction to Tubular Condensers

Tubular condensers are critical components in various refrigeration and heat exchange systems. These devices facilitate the condensation process by allowing gaseous substances to convert into liquid form through heat transfer. This category encompasses a range of designs tailored to specific industry requirements, ensuring that systems operate with optimal efficiency.

Types and Applications

The versatility of tubular condensers is reflected in their wide array of types, including shell and tube, coaxial, and double-pipe configurations. Each type serves distinct applications, from large-scale industrial refrigeration to HVAC systems, and even in power plants where waste heat recovery is crucial.

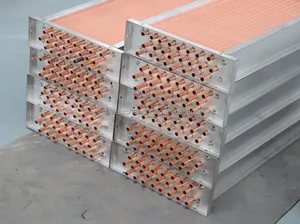

Features and Materials

Tubular condensers are engineered with features that cater to a robust performance. The materials used, such as copper, stainless steel, or titanium, are selected for their thermal conductivity and resistance to corrosion. This ensures that the condensers can withstand harsh conditions and maintain their structural integrity over time.

Advantages of Tubular Condensers

The design of tubular condensers offers several advantages. Their tubular structure allows for efficient heat transfer and ease of maintenance. Additionally, the use of advanced materials contributes to their longevity and consistent performance in diverse operating environments.

Compatibility and Durability

Compatibility is a hallmark of tubular condensers, as they are designed to integrate seamlessly with a variety of equipment. Durability is also a key feature, with resistance to extreme temperatures and humidity, which ensures that these components maintain their functionality over extended periods.

Choosing the Right Tubular Condenser

Selecting the appropriate tubular condenser is crucial for any system. Factors such as size, type, and material composition must be considered to match the specific needs of the equipment. While the choice is vast, the focus should always be on compatibility and the specific demands of the application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4