Popular in your industry

Top categories

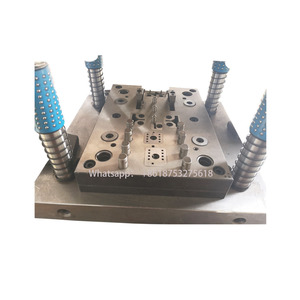

About drawing mold

Drawing Mold Essentials

The term drawing mold encompasses a broad category of tools used in the manufacturing sector to shape materials into precise, intricate designs. These molds are pivotal in processes such as injection molding, where they are instrumental in fabricating both small, complex items and larger, ornamental components. The versatility of mold drawing techniques allows for a wide array of applications, from industrial parts to decorative elements like bolection molds for door plating.

Types and Applications

Moulding drawing technology has evolved to cater to various industry needs, resulting in a spectrum of mold types. From cylindrical mold drawing for symmetrical components to deep drawing mold designs for creating deep, seamless parts, the applications are extensive. Injection mold drawing is particularly prevalent, used in creating parts for automotive, medical, and consumer electronics by transforming material into a desired shape with high precision.

Material Considerations

The choice of material for a drawing mold is critical, impacting the durability and quality of the final product. Options range from robust iron molds to advanced composites, each offering distinct advantages. The material selection is influenced by the intended use of the mold, the complexity of the mold design drawing, and the production environment.

Features and Advantages

A well-crafted drawing mold can significantly streamline production processes. Standardizing elements such as lift bars, connection sizes, and clamp slots can enhance compatibility across various molded products, simplifying operations. Furthermore, the precision of a mold draw ensures repeatability and consistency, which are paramount in mass production. The adaptability of molds to incorporate injection molded part drawing specifications is another key benefit, allowing for customization without sacrificing efficiency.

Optimization and Customization

Suppliers on Alibaba.com understand the importance of mold precision, offering services to refine the mold drawing easy process until the desired outcome is achieved. This often involves creating multiple test samples to ensure the mold meets the exact mould assembly drawing requirements. Such attention to detail facilitates the optimization of the mold for its specific application, which can lead to cost savings in production over time.

Choosing the Right Drawing Mold

Selecting the appropriate drawing mold is a nuanced process that involves considering the design, material, and specific manufacturing needs. Alibaba.com serves as a platform where buyers can connect with experienced suppliers to find the right mold solutions. Whether seeking a face mold drawing or a draw polish mold, the platform offers a diverse range of options to meet various molding demands.